The future of food dyes

By Alessandra Ferrari

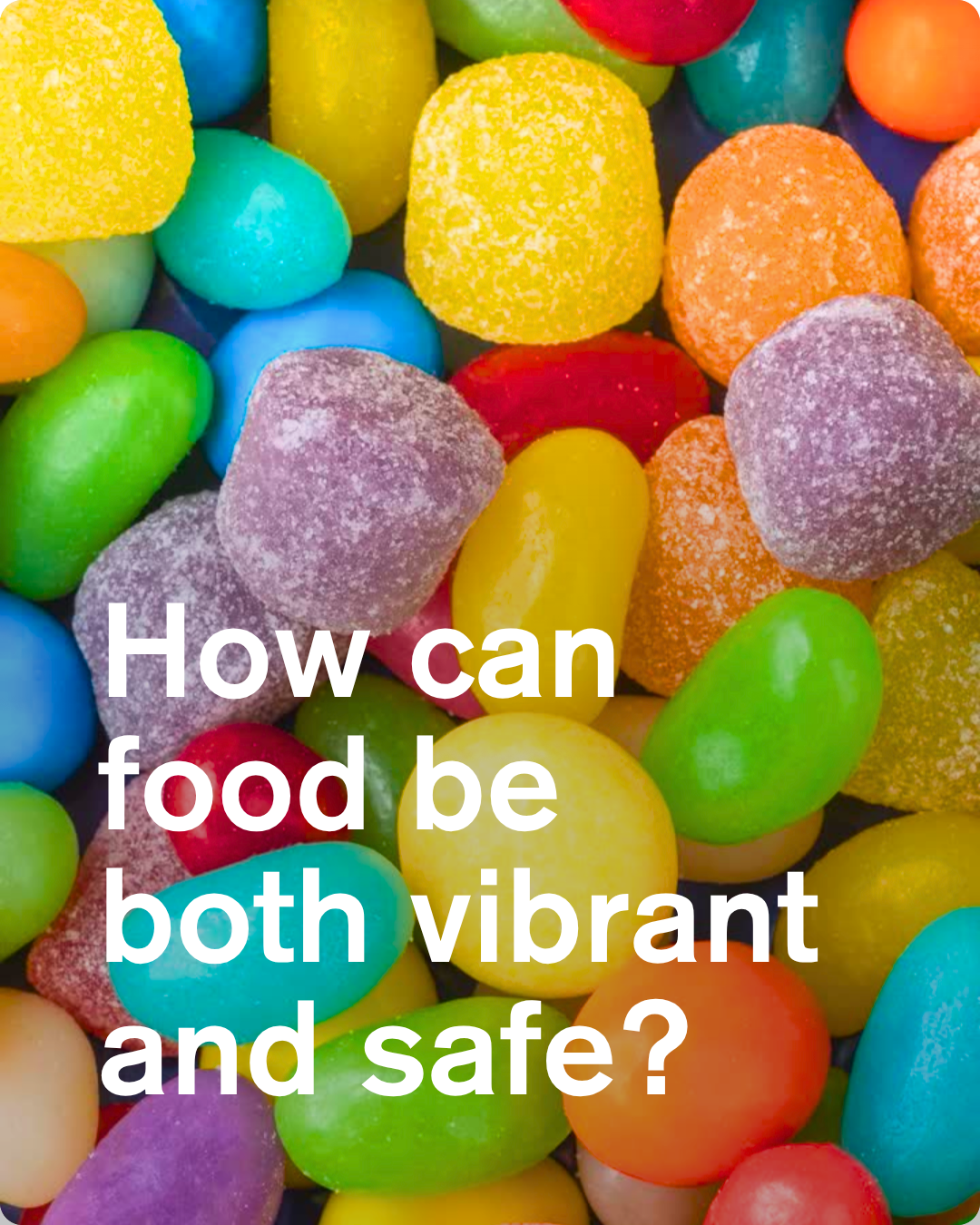

Irina Borodina’s journey into the world of natural dyes is both professional and personal. After many years in Denmark, she and her family developed a beloved tradition known as ‘Friday Candy’ – a weekly movie night with sweet treats. But then Borodina came across a major study by researchers at the University of Southampton, which showed evidence of increased levels of hyperactivity in young children consuming mixtures of some artificial food colours. Many of the candies her family enjoyed contained these synthetic dyes.

This personal concern sparked a professional drive to find safer, healthier alternatives. The cherished tradition of ‘Friday Candy’, together with her commitment to her family’s well-being, continues to inspire her work to transform how food dyes are made and used.

A shift in colouring

The widespread use of synthetic food dyes started in the early 20th century, largely because they provide vibrant colours that enhance the visual appeal of products such as candies, beverages, and baked goods. However, over the years, growing evidence and increased regulatory scrutiny have highlighted their potential health and environmental risks.

Following the 2007 Southampton study, health concerns gained broader attention. In response, the European Union introduced legislation requiring warning labels on products containing specific synthetic dyes. This helped accelerate a shift towards natural alternatives.

In the United States, regulatory bodies and consumer trends are moving in the same direction. A major transformation is underway: the Food and Drug Administration has set a deadline to phase out certain synthetic dyes, including Red 3, which gives some foods a bright cherry-red colour. Meanwhile, California has banned synthetic dyes in school meals, further pushing the industry toward natural solutions.

The move to natural colourants is not only about regulatory compliance but also reflects a broader shift in market expectations. For many companies, replacing synthetic dyes has become a strategic decision, driven by consumers increasingly demanding healthier ingredients, transparency, and sustainability. These factors are increasingly shaping corporate strategies across the food industry.

The potential of biotechnology

Natural food colours are primarily extracted from plants and, in some cases, insects. For example, red betanin comes from red beets, orange beta-carotene from carrots, and yellow curcumin from turmeric. Red carminic acid is extracted from cochineal insects that live on cacti. However, these natural sources contain very low concentrations of food colours, often well below 1%. As a result, extraction is expensive, wasteful, and frequently leads to the co-extraction of impurities, such as nitrates or geosmin, which imparts an earthy smell to beet extracts.

Biotechnology offers a cheaper, more sustainable way to produce natural food colours. For example, yellow riboflavin is now mainly produced through microbial fermentation. While other food colours can also be made by fermentation, this approach requires significant research and process optimisation.

Recent advances, such as those from Irina Borodina’s lab, have demonstrated the potential of yeast-based fermentation processes for producing betalain-type colours. These methods optimise both the yield and purity of natural colourants, significantly reducing the environmental footprint compared to conventional dye production. Notably, switching to fermentative production could reduce land use and climate change impact, measured in CO2 equivalent, by 90% compared to extracting colours from red beets.

Borodina’s work is ground-breaking in its ability to overcome key limitations of plant-based extraction methods. Microbial fermentation enables year-round production of consistent, high-quality colourants, free from the variability caused by farming conditions and seasonal changes. Furthermore, this technology allows for the efficient and low cost production of rare betalains - such as amaranthine found in amaranth flowers or phyllocactin, present in very small amounts in the red dragon fruit - at high purity. These advancements not only ensure a reliable supply of natural dyes but also support the industry's sustainability goals by minimising ecological impact.

The yeast colour palette

‘Producing food colours using yeast fermentation involves several challenging steps, each essential for successful production’, says Borodina. ‘It begins with identifying the right enzymes, which must be carefully selected and combined to work harmoniously, ensuring balanced expression levels to prevent unwanted byproducts. Additionally, the yeast itself must be fine-tuned to direct as much of the feedstock as possible toward creating the desired colour. This is particularly challenging because the pathways required to produce colours do not naturally occur in yeast.’

By engineering these metabolic steps, Borodina can genetically modify yeast strains to efficiently produce natural dyes. Another notable breakthrough from Borodina’s lab is the fermentation-based production of pigments traditionally derived from red beets. Her exploration of unique pigments, such as the bright magenta found in red dragon fruit, underscores the growing potential for exotic, visually appealing dyes. Her innovative fermentation technology not only optimises the yield and purity of natural colourants but is also significantly more eco-friendly.

Beyond food

But the promise of biotechnology extends far beyond the dinner table; its sustainable solutions are also transforming other industries, such as textiles. ‘For instance, current efforts to innovate in textile dyeing aim to replace traditional indigo with bio-based alternatives,’ Borodina explains. For instance, the research group of Ditte Welner at the Center for Biosustainability has developed a novel enzymatic process for jeans dyes that is not toxic to humans or the environment, in contrast to the conventional indigo process used today. This innovation has led to the creation of the start-up Nordic Blue, which is pioneering greener denim production.

This cross-industry impact underscores that the shift to natural, bio-based dyes is not just about cleaner labels on food - it is part of a much wider movement toward healthier, more sustainable production practices. By replacing synthetic dyes with bio-based alternatives, companies across sectors can reduce environmental harm and respond to growing consumer demand for transparency and responsibility.

Borodina’s research lies at the heart of this transition, offering practical solutions to today’s challenges while opening the door to greener innovation across food, textiles, and beyond. As synthetic dyes fade out, her science provides not just replacements but improvements – consistent, sustainable, and safer colourants. 'Each step in this scientific journey is an homage to the cherished family tradition of ‘Friday Candy’, and a commitment to future generations enjoying such pleasures without compromising their health,' says Borodina.

Biography

Irina Borodina is Professor in Yeast Metabolic Engineering at the Novo Nordisk Foundation Center for Biosustainability, Technical University of Denmark (DTU). Her research focuses on advancing the methodologies for metabolic engineering of yeast cell factories for the sustainable production of bulk and high-value chemicals. She received a Chemical Engineering degree from Kaunas University of Technology in Lithuania in 2001 and a PhD degree in Biotechnology from DTU in 2007. She is co-founder and CSO of a biotech start-up company BioPhero that produces insect pheromones for environmentally friendly pest control. She received 2016 Jay Bailey Young Investigator Award in Metabolic Engineering, 2019 Equinor Prize, and was selected a 2019 EU Women Innovator.