Carbon Nanotubes: manufacturing steps to commercialisation

Stronger than steel, conducting electricity better than copper and heat better than diamonds: these are some of the promises held by carbon nanomaterials. Although not as well-known as graphene, carbon nanotubes (CNTs) show these properties – offering also a great advantage: they can be produced in larger quantities. Prof. Michael De Volder now explores new ways to manufacture CNTs-based devices with optimal features, potentially opening the way to their broader commercial use.

While wonder material graphene was first isolated in Manchester in 2004, carbon nanotubes (CNTs) have been actively researched since the 1990s. These cylinders of one or more layers of graphene are already used in nanotechnology, electronics, optics and material science. But many engineering applications are still not possible. The difficulty comes when building larger structures such as wires, as CNTs lose their assets to a great extent.

Prof. De Volder aims to develop new technologies to assemble CNTs into organised, hierarchical superstructures that would retain their exceptional properties. His team brings together engineers, chemists, physicists and material scientists to look at the process at different scales: from material synthesis and surface chemistry at nanoscale, to the form and structure of the material at microscale, up to the larger scale: how to integrate CNTs ‘building blocks’ into 3D all-carbon devices.

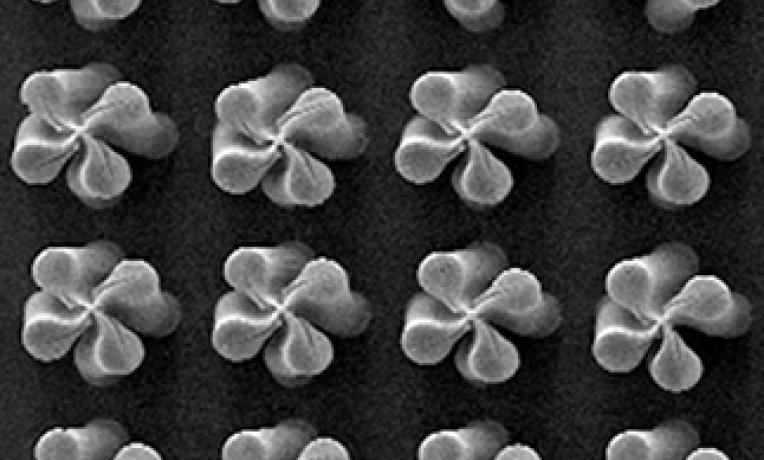

The team has already managed to produce microstructured surfaces with tuneable characteristics such as stiffness or strength. To do so, they provoke the CNTs bending as they grow, managing to form controllable complex shapes in 3D. These compound surfaces could also replicate the water-repellent or adhesive features found in the skins of certain plants or animals for example.

Developed in the HIENA project, the technique is already used to make biomimetic smart surfaces but also chemical microsensors and batteries. Prof. De Volder’s team also works on CNTs application for extremely accurate water purifiers and more efficient energy storage systems for electric cars.